Call +86 138 2971 8317

WeChat: 138 2971 8317

Call +86 138 2971 8317

WeChat: 138 2971 8317

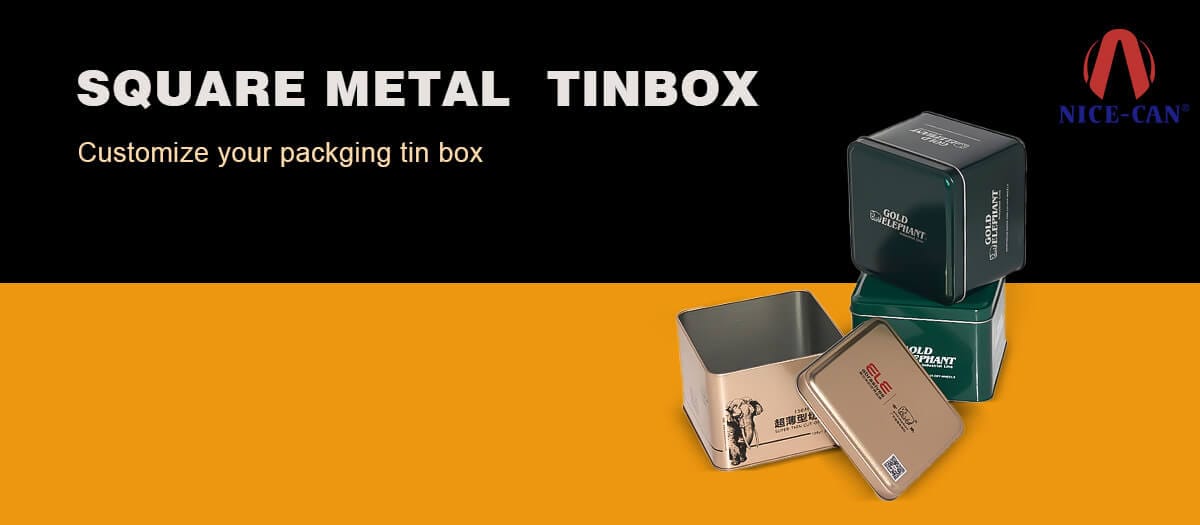

Choose the right product packaging to open the product market, and print a unique logo on the packaging according to the enterprise (brand culture). The product's logo is like a person's ID card, which can enhance the recognition of the product, so it is easier to sell and better protect the product. When consumers buy products, people pay great attention to the packaging of the products. Exquisite packaging is more attractive, but it also reflects the value of the product and reflects the corporate culture. In the packaging industry, we can see that companies are customizing a lot of unique packaging in order to open up a larger market. Food tin box packaging, the quality of food is more guaranteed, because it has good sealing properties, and the light-proof performance prolongs the shelf life of food. To ensure the tin box has these characteristics, the tin box processing manufacturer must pay attention to the manufacturing process of the tin box. The following editors will tell you some important knowledge of making tin boxes:

First, when making a tin box, understand the needs of the customer. Can customize the size, shape, use, quantity, design, printing technology and other basic requirements of the tin box to provide prices to customers. If there is no common size mold, the mold must be made first. Of course, if the tin box manufacturer has a suitable mold, the customer does not need to make a mold, which saves the mold cost for the customer. This is crucial. Some customers have custom developed tin boxes for newly developed products. The manufacturer first asks customers if they can accept existing tin boxes of the same size. If not, develop a new mold.

Second, start making samples after making the mold. Of course, not all customers need samples. Some customers make bulk purchases directly. Some customers still need samples, so why do you want samples? The samples are made by the customer to confirm whether the design meets the requirements, whether the printing color is different, whether the size is correct, etc. Customers can keep abreast of details and appearances and make adjustments.